Common questions about Hinges.

HOW DO I CHOOSE THE RIGHT GRADE OF HINGE?

BS EN 1935 is a performance standard for hinges which are then graded from grade 3 to grade 14. Grade 3 is for hinges to carry a door mass up to 20Kgs and grade 14 is for doors up to 160Kgs. Most of the time it’s not necessary to specify above a grade 11, which covers doors up to 80 kilos in weight. But don’t forget to consider the adjusted door weight with the weight of other hardware added and remember the notional weight adjustment for the effects of a door closer. (See below.)

More information:

IF THERE'S A DOOR CLOSER, WHAT DIFFERENCE DOES THIS MAKE?

A door closer will put extra strain on the hinges due to the extra forces applied by the closer. This has a disproportionate effect on the calculated door weight by around + 20%. If fitting a door closer with a back check function +75% should be added to the actual door weight. If possible try to use longer fixing screws in the hinges for extra support into the door frame.

More information:

WHAT IF MY DOOR IS UNUSUALLY HIGH OR WIDE?

BS EN 1935 offers a chart which explains the increase factor of a door leaf mass as a door becomes wider than 1 metre (1000mm). This is printed in most hinge manufacturers’ literature.

For doors higher than 2.1 metres (2100mm) a fourth hinge should be considered but double check with the manufacturer and ask for the recommended positioning. Remember that if it is a fire door, any extra hinges must be fitted according to the fire test evidence, or be assessed for position by the test house.

More information:

-

GAI Training Manual L1.1 Hinges; Section 8

WHAT SHOULD I LOOK FOR WHEN SPECIFYING HINGES FOR FIRE DOORS?

For any fire doors, ensure the hinges are CE marked. This means the hinges have been manufactured in a quality controlled environment, they have been performance-tested to BS EN 1935, and included as part of a fire doorset test to BS EN 1634-1. Check that the fire test(s) for the hinge were on similar door types to the one on which you want to use the hinge. It’s also worth checking if the hinges need to be fitted with intumescent pads behind the hinge leaves.

More information:

HOW MANY HINGES SHOULD BE FITTED TO A DOOR?

BS 4787-1 states that three hinges per door should be fitted to each door leaf. If doors are taller than 2.1 Metres (2100mm) a fourth hinge should be used. This is fine for non-fire doors. Where fire doors are concerned, the same number of hinges must be fitted as when the doorset was fire tested. This can be critical.

More information:

IF I FIT A FOURTH HINGE DOES THIS AUTOMATICALLY INCREASR THE WEIGHT CARRYING CAPACITY OG THE HINGES?

Normally it is possible to increase the weight carrying capacity of the hinges by approximately 30% by adding a fourth hinge, but this depends on the hinge type, and should always be double-checked with the manufacturer.

WHERE SHOULD I POSITION THE HINGES?

Normally 3 hinges per door leaf fitted 250mm from the top of the door to the centre of the top hinge and 250mm from the bottom of the door to the centre of the bottom hinge the middle hinge should be fitted centrally in the door leaf. For four hinges it’s worth checking with the manufacturer. Where fire doors are concerned, hinges must be fitted in the positions used when the doorset was fire tested. This can be critical.

More information:

WHAT MATERIAL SHOULD THE HINGES I SELECT BE MADAE FROM?

There are pros and cons for all materials:

Stainless Steel

-

Pros:- Strength, high melting point, corrosion-resistance (dependent on grade supplied, 316 being the best)

-

Cons:- Limitation of finishes available, accuracy of rolled joints, cold appearance, little or no anti bacterial properties.

Rolled Steel Hinges

-

Pros:- Strength, high melting point, relatively inexpensive

-

Cons:- Accuracy of rolled joints, low corrosion resistance.

Extruded Brass

-

Pros:- Accuracy and sizes of extruded sections, multitude of finishes available, corrosive resistance, natural anti bacterial qualities

-

Cons:- Low melting point (although certain brass hinges are tested to FD60), hardness of material.

Extruded Aluminium

-

Pros:- Accuracy of extruded sections, relatively inexpensive, corrosive resistance.

-

Cons:- Low melting point (certain aluminium hinges are fire tested), hardness of material There are of course other materials cast iron, cast brass, cast bronze, nylon etc., but the above are the most commonly used materials.

WHAT HINGES SHOULD I USE IN A COASTAL ENVIRONMENT?

Salt water will eventually penetrate most lacquered finishes and cause hinges to discolour, and in the case of steel, start to rust. Marine grade 316 Stainless Steel is the best material for resisting harsh salt water environments and polished unlacquered brass is also excellent, providing it is maintained. It is used by boat and yacht builders. Manufacturers normally offer corrosion resistance test evidence to BS EN 1670, where hinges are hot salt-spray tested for up to 240 hours. If the hinges are CE marked, their corrosion resistance grade is given in the last box of their classification code.

SHOULD I TELL MY CUSTOMERS TO LUBRICATE THE HINGES AFTER FITTING?

It’s always best to refer to the manufacturer’s guide lines, but normally once after fitting and then once every six months with a light oil such as SAE 80 MIN or equivalent is adequate.

Some hinges are maintenance-free which means they require no lubrication because they have special Teflon-type bearings or sinter bearings, which are impregnated with tiny pockets of oil. These will self-lubricate as they start to wear.

HOW SHOULD YOU CLEAN HINGES, ONCE FITTED?

We all hate to see it - beautiful, expensive hinges with paint all over them! It’s obvious but worth a mention to remove or at least mask off hinges when treating timber doors and frames. Some varnishes and stains can attack the finish or base material. General cleaning of hinges should be done with a damp cloth with a light oil or lanolin (ensure you avoid contact with the woodwork). This should be enough to keep the finish in its original condition. Some cleaning agents can also attack the finish of a hinge and could affect the bearings.

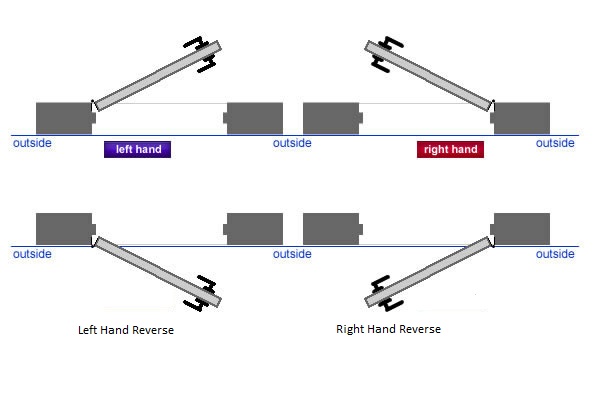

HOW DO I LIFT OFF HINGES AND RISING HINGES?

The GAI and most UK manufacturers refer to the ISO 5 (Clockwise closing) and ISO 6 (Anti- clockwise closing) method of handing. Please double-check this with the manufacturer if in doubt, as some European manufacturers use the German DIN method, and American hinges are handed according to ANSI.

More information:

-

GAI Training Manual L1.6 - Handing of Hardware

WHAT ABOUT ADJUSTMENT ONCE THE DOOR IS FITTED?

Adjustable hinges are available from certain manufacturers. They allow the hinge to be adjusted in situ by means of an Allen key or screwdriver. The hinge can be altered in the height, side and on the compression, enabling the fitter to achieve the perfect gap around the door or alter the door after building settlement, which often causes problems long after the original fitting.

IF I FIT A DOOR IN THE ENTRANCE TO A BUSY OFFICE BUILDING SHOULD I OVER-SPECIFY THE HINGES?

In this type of environment the hinges will operate approximately 1 million times per annum and this requires a heavy duty hinge, which can withstand more than just the weight-carrying requirement. Hinges with maintenance-free bearings and larger hinge knuckles - to give the largest bearing surface - are normally best for these situations. If the hinges look heavy duty enough and the manufacturer’s test evidence reflects the door requirements, they should be up to the job.

When should I use Dog Bolt Hinges?

A dog bolt hinge is specially designed to be used on outward opening external doors. It is a ball bearing hinge that features a bolt through its centre that goes into both frames. The fact that the door is outward opening means that the knuckle of the hinge is exposed to tampering or sawing. If this was to happen to a normal hinge the door would simply fall off the frame resulting in the security of the property being removed. The dog bolt however means the door stays in place keeping the building secure .

You can find our Dog Bolt Hinge here.

Phone: 01 4299399

Phone: 01 4299399